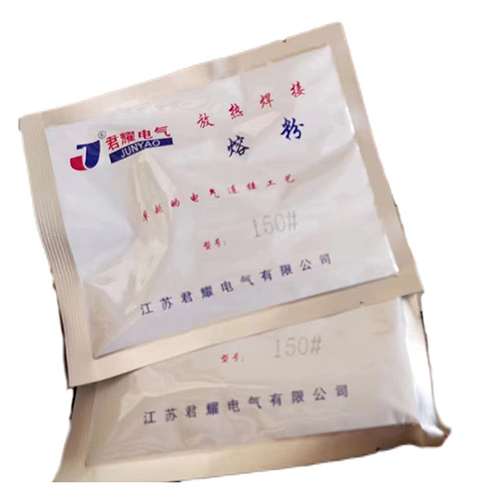

Product Description

Solder powder is a finely ground form of solder alloy that is used in various soldering applications. It is made by melting solder alloys, such as tin-lead or lead-free compositions, and then atomizing or pulverizing them into a powder form. Solder powder is commonly used in industries such as electronics manufacturing, automotive, aerospace, and plumbing.

Here are some key aspects and applications of solder powder:

-

Soldering: Solder powder is primarily used for soldering electronic components onto circuit boards or joining metal surfaces together. It is typically mixed with flux, a chemical cleaning agent that removes oxidation and promotes wetting and adhesion, to form a solder paste. Solder paste is a mixture of solder powder, flux, and a binder that allows precise placement of solder onto specific areas. It is commonly used in surface mount technology (SMT) assembly processes.

-

Wave Soldering: In wave soldering processes, solder powder is employed to create the molten solder wave that flows over the solderable surfaces of circuit boards. The solder powder is melted and sprayed onto a rapidly rotating, heated wheel or wave, creating a controlled flow of molten solder. This technique is widely used for soldering through-hole components on circuit boards.

-

Selective Soldering: Solder powder is also used in selective soldering processes, which involve soldering specific areas or components on a circuit board without affecting other parts. In this method, solder powder is dispensed onto specific solder pads or areas using automated equipment, and then the solder is melted to form the desired solder joints.

-

Repair and Rework: Solder powder can be used for rework and repair applications, where damaged or faulty solder joints need to be removed and replaced. It is often used with a soldering iron or hot air rework station to reflow or replace solder on electronic components and circuit board connections.

-

Plumbing and HVAC Applications: Solder powder is utilized in plumbing and HVAC (heating, ventilation, and air conditioning) systems for joining copper pipes, fittings, and other metal components. The solder powder is mixed with flux, applied to the joint area, and heated to form a strong and leak-free connection.

It's important to note that the use of solder powder should follow proper safety precautions, including adequate ventilation and the use of personal protective equipment, as the handling of solder powder may expose individuals to potentially harmful fumes or lead-containing materials (in the case of tin-lead solder alloys).

Overall, solder powder is a versatile material used in various soldering applications, ranging from electronics manufacturing to plumbing and HVAC systems. It enables the formation of reliable and durable connections between metal surfaces, facilitating the assembly and repair of a wide range of products.

Applications and characteristics of tin solder powder

Tin solder powder, which is primarily composed of tin and may contain small amounts of other elements, has several applications and characteristics. Here are some common applications and characteristics of tin solder powder:

Applications of Tin Solder Powder:

-

Electronics Manufacturing: Tin solder powder is widely used in the electronics industry for soldering electronic components onto circuit boards. It is commonly employed in surface mount technology (SMT) assembly processes, where solder paste, made by combining tin solder powder with flux and a binder, is used for precise placement of solder onto specific areas of the circuit board.

-

Plumbing and HVAC Systems: Tin solder powder is used in plumbing and HVAC systems to join copper pipes, fittings, and other metal components. When mixed with flux and heated, the tin solder powder forms a strong and leak-free connection between the components.

-

Jewelry Making: Tin solder powder is utilized in jewelry making for soldering various metal pieces together. It allows jewelers to create intricate designs and securely join different components.

-

Model Making and Crafts: Tin solder powder can be used in model making, arts, and crafts applications. It enables the joining of metal parts and provides a strong bond.

Characteristics of Tin Solder Powder:

-

Melting Point: Tin solder powder typically has a relatively low melting point compared to other solder alloys, making it suitable for low-temperature soldering applications. The melting point of tin solder powder is around 183°C (361°F) for pure tin, but it can vary depending on the specific composition and any added alloys.

-

Ductility: Tin solder powder exhibits good ductility, meaning it can undergo deformation without breaking. This characteristic allows for reliable and flexible solder joints, which can withstand thermal expansion and mechanical stresses.

-

Wettability: Tin solder powder has excellent wettability, which refers to its ability to spread and adhere to metal surfaces. It forms a thin, uniform layer when melted, ensuring proper contact and bonding with the soldered surfaces.

-

Bright Appearance: Tin solder powder has a bright, silvery appearance when properly soldered. This characteristic is desirable in applications where aesthetics are important, such as jewelry making or decorative soldering.

-

Corrosion Resistance: Pure tin solder powder exhibits good corrosion resistance, making it suitable for certain applications where the soldered joints may be exposed to moisture or other corrosive environments. However, it is worth noting that pure tin solder may be prone to "tin whiskers," which are microscopic growths that can potentially cause short circuits in electronic components.

-

Environmentally Friendly: Tin solder powder is often used in lead-free soldering processes as a substitute for tin-lead solder alloys, which have environmental concerns due to the presence of lead. Lead-free tin solder powder helps meet regulatory requirements and reduces the environmental impact of soldering processes.

When working with tin solder powder, it is essential to follow proper safety guidelines, including adequate ventilation and the use of personal protective equipment, as well as any specific handling instructions provided by the manufacturer.

Overall, tin solder powder is widely used in electronics manufacturing, plumbing, jewelry making, and crafts due to its low melting point, good wettability, and ductility. It provides reliable solder joints and is an environmentally friendly alternative in lead-free soldering applications.

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা

বাংলা  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  Gaeilge

Gaeilge  عربى

عربى  norsk

norsk  اردو

اردو  čeština

čeština  Ελληνικά

Ελληνικά  Українська

Українська  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  ລາວ

ລາວ  Қазақ

Қазақ  Euskal

Euskal  slovenský

slovenský  Македонски

Македонски  Română

Română  Српски

Српски  简体中文

简体中文  Afrikaans

Afrikaans  עִברִית

עִברִית  יידיש

יידיש  Беларус

Беларус  മലയാളം

മലയാളം  Hawaiian

Hawaiian  հայերեն

հայերեն