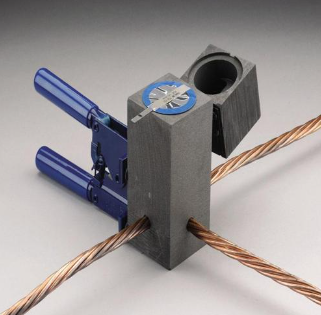

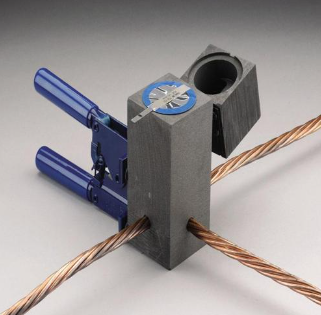

Die clamp: mainly used to clamp the mold, easy to operate. When in use, hold the handle, insert the 4 mold clamp feet into the mold clamp holes and fix them.

Product Details

When it comes to exothermic welding molds, clamps play a crucial role in ensuring a secure and reliable connection between the mold and the conductors being welded. Exothermic welding, also known as thermite welding, is a process used to create permanent electrical connections between two or more metal conductors.

Here's an overview of clamps used for exothermic welding molds:

-

Mold Clamps: Mold clamps are designed to securely hold the exothermic welding mold in place during the welding process. These clamps typically consist of two parts: a stationary clamp and a movable clamp. The stationary clamp is attached to the welding table or workbench, while the movable clamp is adjustable to accommodate different mold sizes. The mold clamps ensure stability and prevent any movement or misalignment of the mold during the exothermic welding operation.

-

Alignment Clamps: Alignment clamps are used to precisely position and align the conductors within the exothermic welding mold before the welding process. These clamps are designed to hold the conductors firmly in place, ensuring that they are correctly positioned within the mold cavities. Alignment clamps help maintain the desired orientation and proximity of the conductors, critical for achieving strong and reliable electrical connections.

-

Grounding Clamps: In exothermic welding, it is essential to establish a proper electrical ground connection. Grounding clamps are used to secure the grounding conductor to the exothermic welding mold. These clamps ensure a solid electrical connection between the mold and the grounding system, allowing the welding process to effectively disperse the molten metal and create a robust welded joint.

-

Safety Clamps: Safety clamps are used to provide additional protection to the operators during the exothermic welding process. These clamps are designed to shield the operator from the sparks, heat, and molten metal generated during the welding operation. Safety clamps are typically made of non-conductive materials and are positioned strategically to minimize the risk of accidental contact with the hot mold or the welding process.

-

Customization: Clamps for exothermic welding molds can be customized to meet specific requirements. They can be designed to accommodate different mold sizes, conductors of various diameters, and specific welding applications. Customization options may include adjustable clamping mechanisms, interchangeable clamp components, or specialized clamps for specific conductor shapes or configurations.

Clamps for exothermic welding molds are essential accessories that ensure proper alignment, stability, and safety during the welding process. They contribute to the overall efficiency, accuracy, and quality of the exothermic welding operation, enabling the creation of durable and reliable electrical connections.

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা

বাংলা  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  Gaeilge

Gaeilge  عربى

عربى  norsk

norsk  اردو

اردو  čeština

čeština  Ελληνικά

Ελληνικά  Українська

Українська  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  ລາວ

ລາວ  Қазақ

Қазақ  Euskal

Euskal  slovenský

slovenský  Македонски

Македонски  Română

Română  Српски

Српски  简体中文

简体中文  Afrikaans

Afrikaans  עִברִית

עִברִית  יידיש

יידיש  Беларус

Беларус  മലയാളം

മലയാളം  Hawaiian

Hawaiian  հայերեն

հայերեն